In fire protection systems, water supply and pressure are critical to ensuring an effective response in emergencies. One of the most efficient ways to boost water pressure in a fire ring main is through a two-port booster system, which works in conjunction with a suction hydrant and a non-return valve. But how does this system actually work?

Let’s break it down in simple terms.

What Is a Fire Ring Main?

A fire ring main is a closed-loop water supply system designed to distribute water evenly around a site for firefighting purposes. It consists of a continuous pipe network that encircles a building, industrial facility, or complex, ensuring that water is always available at various hydrant points.

What Does a Fire Ring Main Include?

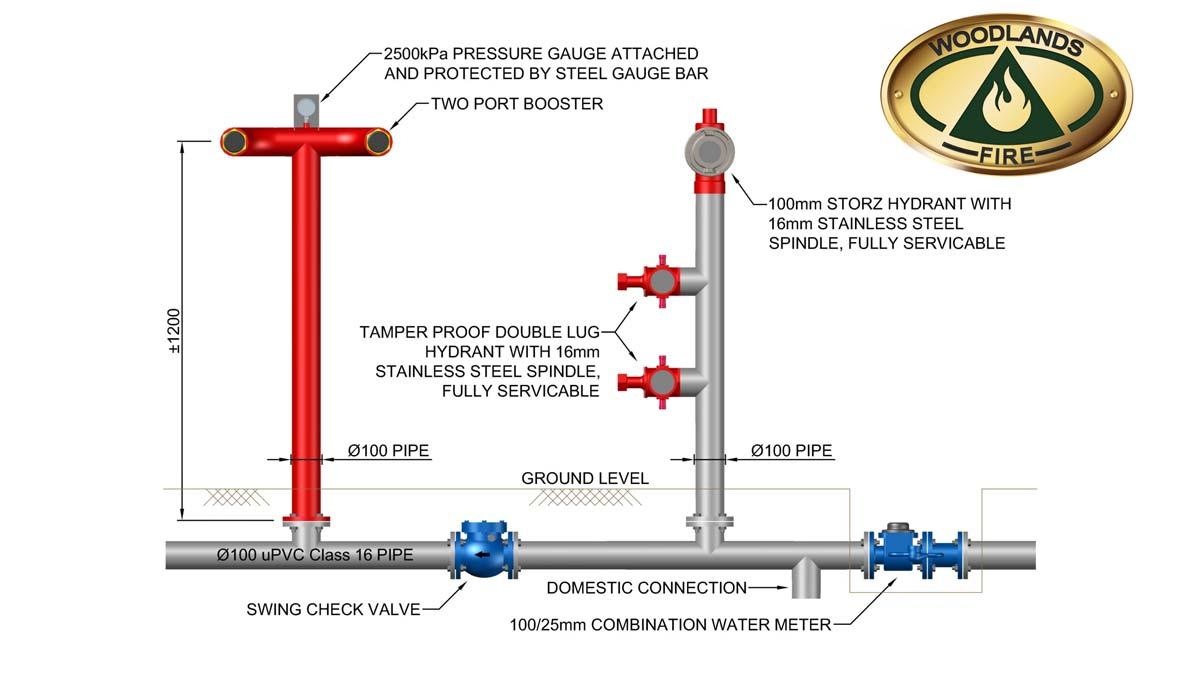

A fire ring main is typically made up of:

✔ Right-angle fire hydrants positioned at key locations.

✔ Hose reels strategically placed throughout the building for easy access.

✔ Two-port booster, allowing fire trucks to increase system pressure.

✔ Suction hydrant, providing a connection point for water extraction.

✔ Non-return valve, ensuring boosted water flows into the system without backflow.

✔ Sprinkler system connections (if applicable) for automated fire suppression.

These components are directly connected to the ring main, ensuring they have a continuous and reliable water supply.

Why Is a Fire Ring Main Important?

✅ Ensures constant water availability—since it forms a loop, water can reach any point in the system from multiple directions.

✅ Prevents water pressure drops—in the event of a fire, the system can distribute water evenly, reducing pressure fluctuations.

✅ Supports multiple firefighting connections—fire hydrants, hose reels, and sprinkler systems can all be connected to the ring main.

However, in large-scale fires, the natural pressure of the municipal water supply may not be sufficient, which is where boosting the pressure becomes essential.

The Role of the Suction Hydrant

During a fire emergency, a fire truck needs access to large volumes of water. The suction hydrant is the connection point that allows the fire truck to draw water directly from the municipal mains. Since municipal mains are pressurised, they provide a steady flow of water, but in large-scale fire incidents, the pressure may not be sufficient for multiple hydrants or hose reels in the system.

Once the fire truck is connected to the suction hydrant and has drawn water, it must increase the pressure before distributing it back into the fire ring main. This is where the two-port booster comes in.

The fire truck connects a high-pressure hose from its pump outlet to the two-port booster, which forces water back into the system at a higher pressure.

This increases the water pressure available to:

✅ Firefighters using right-angle hydrants

✅ Fire hose reels installed throughout the building

✅ Sprinkler systems (if connected to the fire ring main)

Boosting Pressure for Firefighting Operations

Firefighting operations are designed to increase the pressure available to these components, ensuring that the hydrants and hose reels are fully functional and capable of delivering high water flow when needed.

The Importance of a High-Quality Hose

The hose used to connect the suction hydrant and the two-port booster plays a critical role in the system’s reliability. Since firefighters are working with high-pressure water flow, the hose must be:

✔ Durable and reinforced to handle extreme pressure.

✔ Resistant to bursting or splitting, even under heavy strain.

✔ Compliant with firefighting standards to ensure safety and performance.

If a low-quality hose with low pressure resistance is used, there is a higher risk of failure, which could:

⚠️ Disrupt the firefighting operation.

⚠️ Reduce available pressure for hydrants and hose reels.

⚠️ Cause delays that could lead to greater fire damage.

To ensure reliability, firefighters should always use approved high-pressure hoses that meet industry standards for fire suppression applications.

A non-return valve (also known as a check valve) is installed between the two-port booster and the suction hydrant. This is a critical component because it ensures that once the fire truck boosts the water pressure, the water only flows into the fire ring main and does not return to the municipal mains.

Without a non-return valve, there is a risk that:

⚠️ The boosted water pressure could backflow into the municipal water system, potentially causing damage or contaminating the supply.

⚠️ The fire truck’s effort to increase water pressure would be wasted, as the pressure would escape back into the municipal main instead of feeding the hydrants and hose reels in the fire system.

By ensuring the correct installation of a non-return valve, the system maximises water pressure and provides a reliable firefighting solution.

Why This System Is Essential

✅ Increases available pressure for hydrants and hose reels

✅ Prevents backflow into the municipal system

✅ Allows firefighters to maximise water supply during an emergency

✅ Ensures compliance with fire protection system designs

Properly installed two-port boosters, suction hydrants, and non-return valves are essential for any fire ring main system. They provide a robust and effective solution to enhance water pressure and improve fire suppression capabilities when they’re needed most.

If you need more information about how to correctly install and maintain a two-port booster system, feel free to contact Woodlands Fire for expert guidance and locally manufactured fire protection solutions.